| The formation of Blackhall Engineering in 1965 marked the beginning of an ongoing commitment to design and manufacture special purpose valves to the customer's exact requirements. The breadth of our experience and resulting products over this period has encompassed services from high pressure/temperature applications to cryogenics and our valves have been used to control fluids from service air to liquid helium, from fuel oil to crude and from boiler-feed water to superheated steam. Within our design parameters, we strive to provide our customers with longevity in the product and ease of on-site maintenance. We also help to keep our customer's operating costs to a minimum by providing a full spares service and reconditioning facility for our own and other manufacturer's products. |

Blackhall

Engineering

Series 6000

Automatic Recirculation Valve

Please

contact

Anderson-Brooksbank USA,

LLC

for a full Brochure and Data Manual

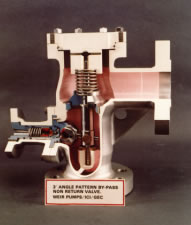

The Blackhall range of Automatic Recirculation Valves have been designed to give absolute reliability with maintenance requirements minimized. Each Blackhall valve is designed specifically to suite the individual customers' requirements. The range includes both ON/OFF and Modulating options with options available in Angle or Straightway pattern design. The Angle patterns valve has the additional feature of not requiring removal from the pipeline during maintenance 'Shut downs.'

By-Pass Configuration ON/OFF

The Blackhall ON/OFF Automatic Recirculation valve is really a system which incorporates five functions in one:

(1) Non-Return Valve:

preventing reverse flow through the centrifugal pump via the main line.

(2) By-Pass Control Valve: protecting the pump overheating by regulating

a passage of fluid through the pump during START UP, SHUT DOWN and when

the pump is run against a closed outlet.

(3) Flow Sensing

Capability: which actuates the bypass control valve.

(4) Pressure Reduction Nozzles: which dissipate the pressure energy

and allows the line fluid to be delivered to the by-pass system quietly

and safely.

(5) Non-Return Valve: preventing reverse flow through the centrifugal

pump via the the by pass line.

Introduction

to the

Automatic Recirculation Valve

The

demands of modern industrial processes has led to the need for higher

and higher pressure. This in turn has created a need for centrifugal pumps

with high heads and low specific speeds. Tolerances within such pumps

have become smaller and this has led to the pumps being more sensitive

to temperature increases. It is therefore essential that the flow through

such pumps should not fall below minimum cooling quantities. The design

of the flow control system for centrifugal pumps therefore demands certain

essential functions:

(1) Protection against pump overheating due to minimum cooling flow not

being maintained.

(2) The ability to rapidly build pressure to achieve hydraulic balance

on start up.

(3) Protection against flow reversal from the feed line on pump shut down.

P.O. Box 38694

Greensboro, NC 27438

Phone: 336-944-5702

E-Mail: info@brooksbankvalvesusa.com

Valves Site Map